The holiday season is when people rush to treat themselves or buy gifts for others, helping ecommerce businesses land more sales.

But this shopping frenzy comes with plenty of issues—and one of the most common is holiday shipping delays.

Starting around Black Friday and Cyber Monday and all the way through Christmas and New Year’s, your sales are likely to go up—which means so are shipping delays.

Incorrect order information, logistical and supply chain disruption, and inclement weather events can all prevent your products from reaching their destinations on time.

Shipping delays are one of the fastest routes to unhappy customers, negative reviews, and reduced revenue potential during the busiest period of the year—and that means you should do everything in your power to prevent and plan ahead for them.

To help you avoid holiday shipping delays and minimize stress during the busiest time of year for ecommerce businesses, we bring you a collection of valuable tips and communication examples from real brands.

1. Plan ahead for the busy holiday season

In the peak holiday shopping period, any ecommerce business with an efficient marketing and CRM strategy can expect a surge in orders. If you’re not prepared for this increase, your business may get stuck in what seems like a never-ending circle of incomplete or wrong orders, inventory issues, and unhappy shoppers.

Planning is key to avoiding these problems. Start by checking the shipping deadlines before the holiday season and marking them in your calendar so you can plan around them.

Then, consider taking a few more steps before the season starts to be better prepared:

Examine the supply chain.

1

Analyze your entire supply chain to resolve any bottlenecks before the peak shopping season. Identify potential issues, like a lack of materials or transportation problems, and create a game plan to overcome them, like ordering more packing supplies or securing additional carriers.

Secure labor.

2

The surge in orders naturally requires more hands on deck. Talk to your employees early on to discuss their availability and create a rough schedule. If you offer delivery, check how much work your carriers can take on during the busy period.

Evaluate your shipping policies.

3

Rethink your shipping policies before the holiday season to accommodate potential delays and keep your customers satisfied.

Ask existing customers about their experience with their orders through forms and surveys. Their answers will help you objectively gauge how efficient your shipping system is when it’s not busy so you can understand what to improve in time for holidays.

Holiday shipping tip: Don’t wait until the holiday season is around the corner to start planning. To minimize stress and keep customers happy, give yourself a few months’ leeway to accommodate potential changes.

2. Communicate transparently with your customers

After planning, the single most important step you can take to minimize shipping delays this holiday season is to communicate.

Communicating potential issues clearly and transparently to your customers is key to overcoming shipping delays, as it helps maintain their trust in your brand and minimize dissatisfaction.

This BFCM season, keep these communication tips in mind:

Don’t make promises you can’t keep.

1

Same-day or next-day delivery during peak season may sound like a dream come true, but it’s often not doable. If you’re not 100% sure you can pull it off, it’s best to allow for some cushion time in case of unforeseen circumstances.

Inform customers about projected shipping timelines.

2

Communicate shipping deadlines as well as potential shipping delays due to the holiday rush even before customers place their orders. You can do so through your email and SMS channels or by posting a message on your website.

Keep customers updated about their orders.

3

In addition to automated order confirmation messages, shipping confirmation messages, and delivery confirmation messages, which you set up during the planning process in step 1, consider implementing delayed shipment flows to communicate issues. In this case, less is more doesn’t apply—customers will appreciate your involvement and dedication in communicating every change.

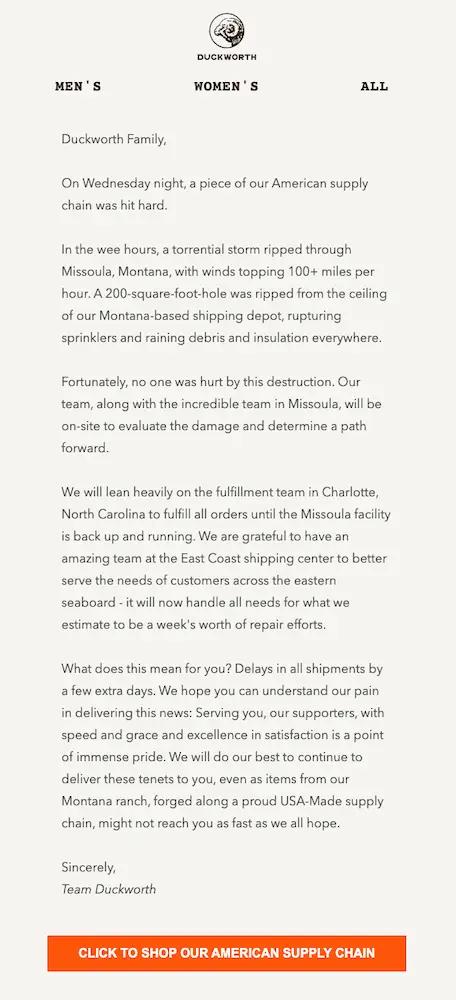

Take a look at how clothing brand Duckworth notifies their customers of severe weather conditions affecting their American supply chain. The email clearly outlines the consequences of the storm for the brand’s customers, announcing potential delays and asking for their understanding:

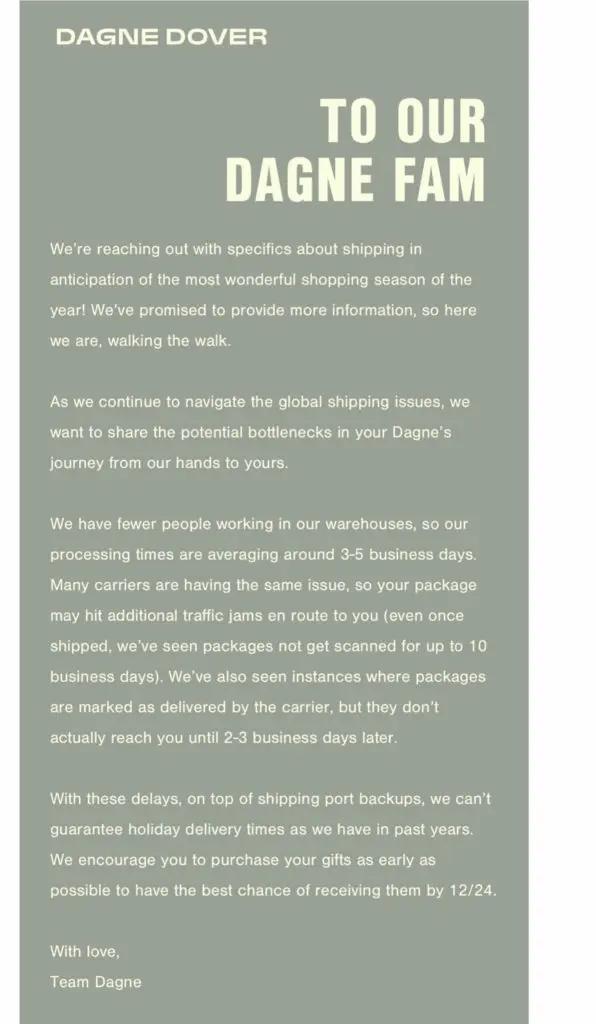

Here, bag brand Dagne Dover takes a similar approach, sharing a candid update that explains the longer processing times and shipping delays the brand experiences during the holiday season. The email addresses their customers in a friendly manner and tone, cultivating a stronger, more inclusive connection.

3. Give people a good reason to order early

Another way to avoid shipping delays during BFCM season is to encourage your customers to get their orders in early. Spacing out orders minimizes the risk of operational issues due to too many orders at once, helping make sure your business doesn’t end up with an overwhelming backlog.

Here are a few ways to encourage people to place their orders early:

Launch your holiday sales and promotions early.

1

To drive success with early orders, drop your sales and campaigns at the onset of the holiday season—or even earlier. Take POPFLEX as an example: the activewear brand promoted an early BFCM giveaway in October, then used the data they gathered from it to fine-tune their campaign messaging in time for a successful BFCM season.

Offer an incentive for shopping early.

2

Encourage your customers to act fast by offering them an early-bird discount, free gift, or bundle promotion. Consider setting a specific date as a discount deadline and add countdown timers to your forms and emails to create a sense of urgency.

Highlight the benefits of early shopping.

3

Send emails promoting the softer advantages of ordering early, like convenience, reduced risk of delays, and peace of mind.

In this Black Friday promotional email, Current Catalog, a brand that offers greeting cards, office supplies, and more, encourages shoppers to beat the holiday rush with a gift-themed message that emphasizes acting fast. In exchange for doing so, customers will receive free shipping plus 10% off all orders.

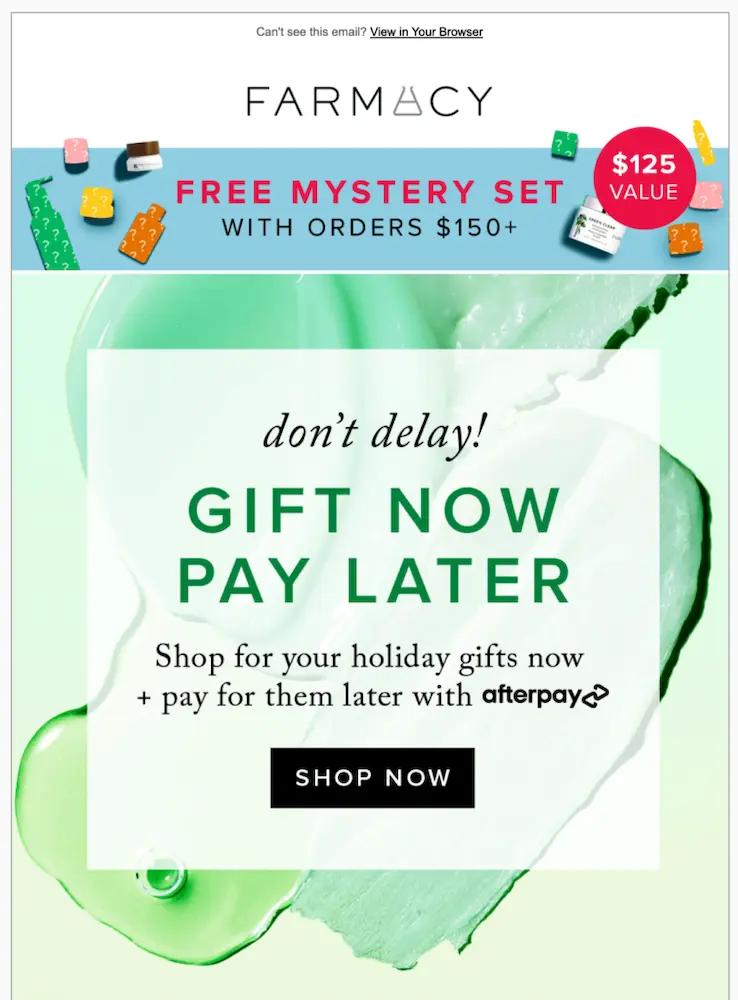

If you’re not a discount brand, you have other options for incentivizing your customers to order early. Here, beauty brand Farmacy takes a more creative approach in their holiday promo email, offering those who “don’t delay” with their orders the option to gift now, pay later using Afterpay.

Holiday shipping tip: The opportunity to buy now, pay later is a unique holiday incentive that’s worth experimenting with instead of offering a universal discount in exchange for early orders. Other non-discount incentives to consider include free entry to a contest, free gifts with purchase, and free shipping when customers spend above a certain threshold.

Speaking of free shipping…

4. Consider offering free shipping

When customers pay for shipping, they may not be as accepting of potential issues with their orders. But offering free shipping might make them a bit more forgiving.

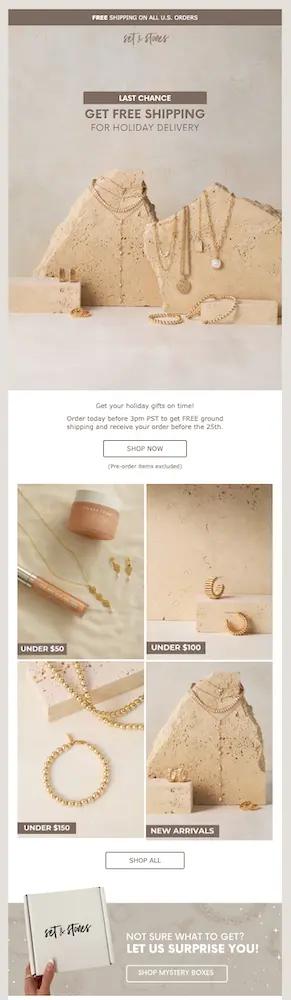

Before the season even begins, you can send out texts or emails to announce free shipping during the holidays and encourage shoppers to buy your products. Here, see how jewelry brand Set & Stones combines their free holiday shipping announcement with a “last chance” disclaimer to create urgency:

Holiday shipping tip: If offering free shipping on everything doesn’t make financial sense for your brand, consider these modified options:

Set a minimum order threshold to qualify for free shipping.

Make free shipping available only for specific products.

5. Reduce mistakes in customer information

If your customers input the wrong information on your order or check-out page, it can trigger delays and issues with order fulfillment.

Here are a few steps you can take to minimize the risk of wrong phone numbers and addresses or typos in customer information:

Create autofill forms where customer information is automatically populated with pre-saved information.

Create forms with dropdown lists so that customers can choose from available options, rather than accidentally inputting invalid or incorrect data.

Ask customers to provide an additional phone number if the primary one isn’t available.

Highlight fields containing obvious errors, such as phone numbers with too many digits or non-existent addresses.

Instruct customers to double-check their information before placing an order or add a pop-up that asks them to confirm the provided data.

Holiday shipping tip: A marketing platform like Klaviyo takes care of this for you by capturing customer data from multiple systems, both internal and external, and storing that information in unique customer profiles. This way, your business can track customer behavior over time and be confident that the data you’ve collected is always accurate and up to date.

6. Share real-time order tracking

Customers appreciate transparency, so real-time order tracking can make them more likely to reorder. Plus, if they can track their orders live, they’ll be less likely to call your customer service team about their order status, and less likely to miss a delivery.

Keep every customer informed of their order status by providing them with a link for real-time tracking in your transactional emails and transactional texts. This way, they can see changes as they happen, so they don’t have to wonder what’s going on with their shipment.

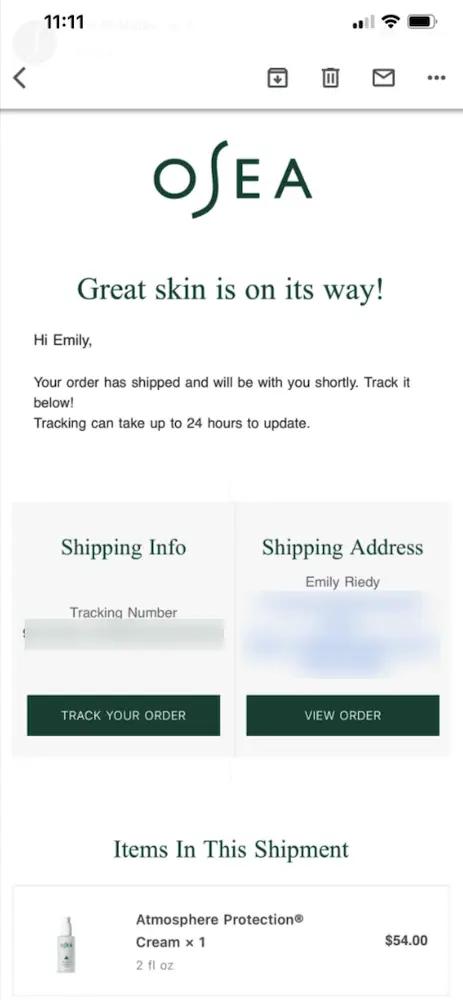

Share tracking links in your order and shipping confirmation email and texts, like vegan skincare brand OSEA does here:

Holiday shipping tip: SMS is a particularly smart channel for transactional updates. According to Klaviyo’s 2024 global texting takeaways report, transactional messages are the No. 1 type of communication consumers prefer to receive via SMS rather than email.

7. Suggest alternatives for out-of-stock products

From one perspective, running out of inventory during the holiday season is a compliment: it means people love your product. But it means you’re guaranteed to end up with some unhappy customers.

To make the most of a potentially bad situation, use email and SMS to suggest product alternatives your customers can order right away, or enable back-in-stock notifications to let shoppers know when they can come back to order what they wanted without delays.

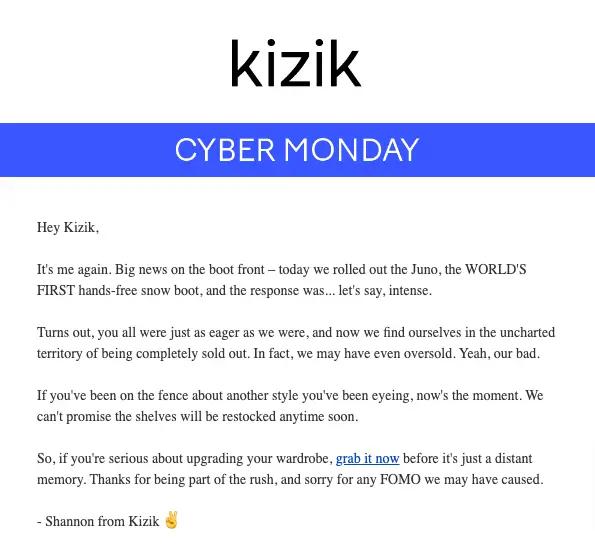

Here, footwear brand Kizik gets ahead of Cyber Monday stockout issues by sending an apologetic email along with a link to alternative shoe styles disappointed shoppers can browse:

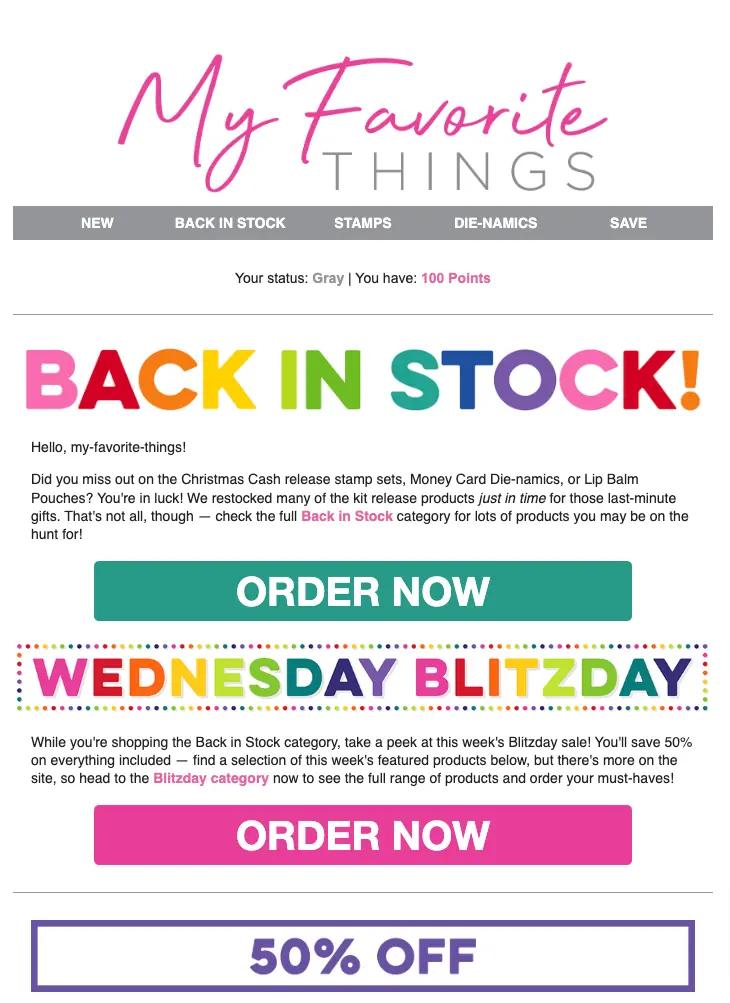

Stamp and dye brand My Favorite Things, meanwhile, avoids missing out on Christmas sales by sending out a back-in-stock email inviting customers to continue shopping for the gifts they originally wanted:

8. Offer local pickup options for customers in your area

To help minimize the burden on the transportation industry and get your products in the hands of your customers faster, you can arrange local pickups for customers in your area so they don’t have to pay for shipping or wait days to receive their orders.

This option also means you don’t have to coordinate shipping and can save on packaging materials and resources.

Here, cosmetics brand Sly Beauty spreads the word about their local pickup option in an email campaign before customers place their orders. The straightforward email clearly outlines the location, dates, and times when pickup will take place, as well as a short explanation of how to select this option when checking out online:

Holiday shipping tip: If you offer local pickup, make sure you add it as an option during your check-out process. Then, update your order confirmation email templates to include details on exactly when and where customers can pick up their items.

9. Set up additional fulfillment centers or find a 3PL partner

Shipping from a single location may be more convenient, but it’s also risky—in case of severe weather in the area or not enough hands on deck, you’ll have no way to ship orders.

Instead of keeping all your eggs in one geographical basket, it’s a good idea to set up additional fulfillment centers to streamline your operations and ensure timely deliveries.

Of course, for many ecommerce brands, this is easier said than done.

In the meantime, consider a more affordable and realistic option: partnering with a third-party logistics (3PL) company to help with order fulfillment and keeping your team’s heads above water.

Once the holidays are over and the excitement settles down, take some time to reflect on the season behind you. Analyze your workflows, shipping policies, and timelines, talk to your suppliers, and see what worked well and what requires improvement.

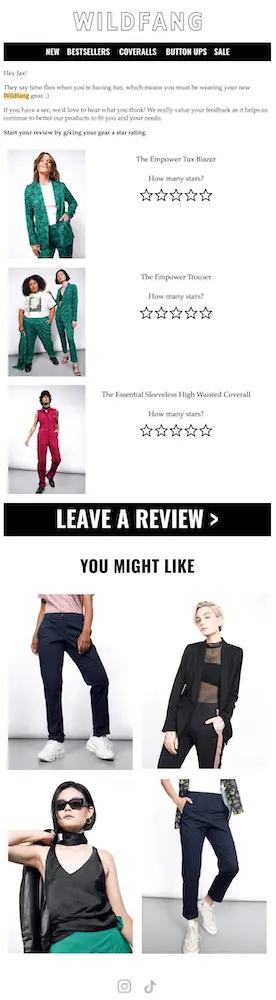

Gathering customer feedback is another vital part of this process. Once customers receive their orders, ask them about their experience and overall satisfaction with the process, like genderless apparel brand Wildfang does with this review request email. You can use the information you collect to improve your processes down the line.

By conducting a thorough analysis of your holiday season’s ups and downs, you’ll lay the groundwork for the year ahead. This will lead to even more satisfied customers and fewer issues down the line.

Holiday shipping tip: Collecting user-generated content like customer reviews and testimonials is a great way to let your happiest customers do your marketing for you. Take a leaf out of Compass Coffee’s book and set up your review request flows to incentivize customers to leave reviews with a visual element, which will be easier to incorporate into your marketing efforts.

Keep your promises to your customers with Klaviyo

Sometimes, holiday shipping delays are inevitable despite your best efforts. They can result from factors beyond your control, such as bad weather, carrier strikes, or transportation issues.

But as long as you do everything in your power to keep your customers informed about the status of their orders, you’ll be on the right track to overcoming shipping delay troubles and making it out of the holiday season with your most prized customer relationships intact.

Customer satisfaction should be at the forefront of your priorities all year long—not just when the fallout from a global shipping backlog threatens to erode your brand’s reputation. The key, as usual, is clear communication. With the right email and SMS automations, your customers will always know exactly what to expect.

Klaviyo helps you manage your post-purchase communications with maximum transparency, protecting your brand’s bottom line during the most wonderful, and hectic, time of the ecommerce year.

Nevena Radulovic is a seasoned content editor and writer with experience in researching and refining content across multiple platforms and niches, including finance, marketing, and retail. Having studied linguistics at a high level, Nevena places a strong focus on clarity and accuracy.

Looking for the right ecommerce platform? Explore 19 top ecommerce platforms for B2C brands in 2026, with key strengths, ideal use cases, and ecommerce software integrations that help you scale.

Compare the best loyalty program software for B2C brands in 2026. Explore loyalty program management platforms that boost retention, LTV, and repeat purchases.

# How to keep your promises: 10 holiday shipping tips for brands that want to avoid ecommerce shipping delays

The holiday season is when people rush to treat themselves or buy gifts for others, helping ecommerce businesses land more sales.

But this shopping frenzy comes with plenty of issues—and one of the most common is holiday shipping delays.

Starting around [Black Friday and Cyber Monday](https://www.klaviyo.com/solutions/bfcm) and all the way through [Christmas](https://www.klaviyo.com/blog/christmas-email-marketing) and New Year’s, your sales are likely to go up—which means so are shipping delays.

Incorrect order information, logistical and supply chain disruption, and inclement weather events can all prevent your products from reaching their destinations on time.

Shipping delays are one of the fastest routes to unhappy customers, negative reviews, and reduced revenue potential during the busiest period of the year—and that means you should do everything in your power to prevent and plan ahead for them.

To help you avoid holiday shipping delays and minimize stress during the busiest time of year for ecommerce businesses, we bring you a collection of valuable tips and communication examples from real brands.

## 1. Plan ahead for the busy holiday season

In the peak holiday shopping period, any ecommerce business with an efficient marketing and [CRM strategy](https://www.klaviyo.com/platform/crm-strategy) can expect a surge in orders. If you’re not prepared for this increase, your business may get stuck in what seems like a never-ending circle of incomplete or wrong orders, inventory issues, and unhappy shoppers.

Planning is key to avoiding these problems. Start by checking the shipping deadlines before the holiday season and [marking them in your calendar](https://www.klaviyo.com/solutions/bfcm/calendar) so you can plan around them.

Then, consider taking a few more steps before the season starts to be better prepared:

```json

{

"_key": "7e3da575-8854-4bb0-8e9b-7675000495d7",

"_type": "steps",

"steps": [

{

"_key": "ad7ad971-69bb-4272-94ba-a6fe734b1454",

"_type": "step",

"body": [

{

"_key": "oR5rmzJRTTTXSt7VQbhpcO",

"_type": "block",

"children": [

{

"_key": "oR5rmzJRTTTXSt7VQbhpd4",

"_type": "span",

"marks": [],

"text": "Analyze your entire supply chain to resolve any bottlenecks before the peak shopping season. Identify potential issues, like a lack of materials or transportation problems, and create a game plan to overcome them, like ordering more packing supplies or securing additional carriers."

}

],

"markDefs": [],

"style": "normal"

}

],

"title": "Examine the supply chain."

},

{

"_key": "a3ef6b6a-c428-43f0-92b2-5ef643c27472",

"_type": "step",

"body": [

{

"_key": "oR5rmzJRTTTXSt7VQbhpdk",

"_type": "block",

"children": [

{

"_key": "oR5rmzJRTTTXSt7VQbhpeQ",

"_type": "span",

"marks": [],

"text": "The surge in orders naturally requires more hands on deck. Talk to your employees early on to discuss their availability and create a rough schedule. If you offer delivery, check how much work your carriers can take on during the busy period."

}

],

"markDefs": [],

"style": "normal"

}

],

"title": "Secure labor."

},

{

"_key": "102b4f2b-e0b5-40a6-9c2e-ad29229dd188",

"_type": "step",

"body": [

{

"_key": "oR5rmzJRTTTXSt7VQbhpf6",

"_type": "block",

"children": [

{

"_key": "oR5rmzJRTTTXSt7VQbhpfm",

"_type": "span",

"marks": [],

"text": "Rethink your shipping policies before the holiday season to accommodate potential delays and keep your customers satisfied."

}

],

"markDefs": [],

"style": "normal"

}

],

"title": "Evaluate your shipping policies."

},

{

"_key": "4dfca319-61c3-4b50-852b-3d2f45172142",

"_type": "step",

"body": [

{

"_key": "oR5rmzJRTTTXSt7VQbhpgS",

"_type": "block",

"children": [

{

"_key": "oR5rmzJRTTTXSt7VQbhph8",

"_type": "span",

"marks": [],

"text": "If you’re not sure how to streamline customer communication at every stage of their journey, make sure you set up "

},

{

"_key": "oR5rmzJRTTTXSt7VQbhpho",

"_type": "span",

"marks": [

"link-4e7fptr"

],

"text": "order confirmation flows"

},

{

"_key": "oR5rmzJRTTTXSt7VQbhpiU",

"_type": "span",

"marks": [],

"text": ", "

},

{

"_key": "oR5rmzJRTTTXSt7VQbhpjA",

"_type": "span",

"marks": [

"link-m9cf8x5"

],

"text": "shipping confirmation flows"

},

{

"_key": "oR5rmzJRTTTXSt7VQbhpjq",

"_type": "span",

"marks": [],

"text": ", and "

},

{

"_key": "oR5rmzJRTTTXSt7VQbhpkW",

"_type": "span",

"marks": [

"link-bpqo190"

],

"text": "delivery confirmation flows"

},

{

"_key": "oR5rmzJRTTTXSt7VQbhplC",

"_type": "span",

"marks": [],

"text": " across email and SMS well before the holiday season rolls around."

}

],

"markDefs": [

{

"_key": "link-4e7fptr",

"_type": "link",

"href": "https://www.klaviyo.com/blog/order-confirmation-email-tips-examples",

"openInNewTab": true

},

{

"_key": "link-m9cf8x5",

"_type": "link",

"href": "https://www.klaviyo.com/blog/tips-better-shipping-confirmation-emails",

"openInNewTab": true

},

{

"_key": "link-bpqo190",

"_type": "link",

"href": "https://community.klaviyo.com/campaigns-and-flows-30/delivered-shipment-email-in-klaviyo-9454",

"openInNewTab": true

}

],

"style": "normal"

}

],

"title": "Set up automations to keep customers informed."

},

{

"_key": "2ef958ba-05d3-4264-98c8-767f79d5675a",

"_type": "step",

"body": [

{

"_key": "oR5rmzJRTTTXSt7VQbhpls",

"_type": "block",

"children": [

{

"_key": "oR5rmzJRTTTXSt7VQbhpmY",

"_type": "span",

"marks": [],

"text": "Ask existing customers about their experience with their orders through forms and surveys. Their answers will help you objectively gauge how efficient your shipping system is when it’s not busy so you can understand what to improve in time for holidays."

}

],

"markDefs": [],

"style": "normal"

}

],

"title": "Collect customer feedback."

}

]

}

```

**Holiday shipping tip: **Don’t wait until the holiday season is around the corner to start planning. To minimize stress and keep customers happy, give yourself a few months’ leeway to accommodate potential changes.

## 2. Communicate transparently with your customers

After planning, the single most important step you can take to minimize shipping delays this holiday season is to communicate.

Communicating potential issues clearly and transparently to your customers is key to overcoming shipping delays, as it helps maintain their trust in your brand and minimize dissatisfaction.

This BFCM season, keep these communication tips in mind:

```json

{

"_key": "6afd52ad-51ce-43ff-8064-f2130c36991d",

"_type": "steps",

"steps": [

{

"_key": "ac1ec4db-fea3-430e-970e-7af5d3adf222",

"_type": "step",

"body": [

{

"_key": "oR5rmzJRTTTXSt7VQbhpug",

"_type": "block",

"children": [

{

"_key": "oR5rmzJRTTTXSt7VQbhpvM",

"_type": "span",

"marks": [],

"text": "Same-day or next-day delivery during peak season may sound like a dream come true, but it’s often not doable. If you’re not 100% sure you can pull it off, it’s best to allow for some cushion time in case of unforeseen circumstances."

}

],

"markDefs": [],

"style": "normal"

}

],

"title": "Don’t make promises you can’t keep."

},

{

"_key": "0b102c5b-907c-4ede-8891-045056ec1708",

"_type": "step",

"body": [

{

"_key": "oR5rmzJRTTTXSt7VQbhpw2",

"_type": "block",

"children": [

{

"_key": "oR5rmzJRTTTXSt7VQbhpwi",

"_type": "span",

"marks": [],

"text": "Communicate shipping deadlines as well as potential shipping delays due to the holiday rush even before customers place their orders. You can do so through your email and SMS channels or by posting a message on your website."

}

],

"markDefs": [],

"style": "normal"

}

],

"title": "Inform customers about projected shipping timelines."

},

{

"_key": "46eca673-fdf5-4dc5-b132-fd5808d3fa71",

"_type": "step",

"body": [

{

"_key": "oR5rmzJRTTTXSt7VQbhpxO",

"_type": "block",

"children": [

{

"_key": "oR5rmzJRTTTXSt7VQbhpy4",

"_type": "span",

"marks": [],

"text": "In addition to automated order confirmation messages, shipping confirmation messages, and delivery confirmation messages, which you set up during the planning process in step 1, consider implementing "

},

{

"_key": "oR5rmzJRTTTXSt7VQbhpyk",

"_type": "span",

"marks": [

"link-8qxexgl"

],

"text": "delayed shipment flows"

},

{

"_key": "oR5rmzJRTTTXSt7VQbhpzQ",

"_type": "span",

"marks": [],

"text": " to communicate issues. In this case, less is more doesn’t apply—customers will appreciate your involvement and dedication in communicating every change."

}

],

"markDefs": [

{

"_key": "link-8qxexgl",

"_type": "link",

"href": "https://community.klaviyo.com/campaigns-and-flows-30/delayed-shipment-flow-email-5333",

"openInNewTab": true

}

],

"style": "normal"

}

],

"title": "Keep customers updated about their orders."

}

]

}

```

Take a look at how clothing brand [Duckworth](https://www.duckworthco.com/) notifies their customers of severe weather conditions affecting their American supply chain. The email clearly outlines the consequences of the storm for the brand’s customers, announcing potential delays and asking for their understanding:

Here, bag brand [Dagne Dover](https://www.dagnedover.com) takes a similar approach, sharing a candid update that explains the longer processing times and shipping delays the brand experiences during the holiday season. The email addresses their customers in a friendly manner and tone, cultivating a stronger, more inclusive connection.

## 3. Give people a good reason to order early

Another way to avoid shipping delays during BFCM season is to encourage your customers to get their orders in early. Spacing out orders minimizes the risk of operational issues due to too many orders at once, helping make sure your business doesn’t end up with an overwhelming backlog.

Here are a few ways to encourage people to place their orders early:

```json

{

"_key": "cd9eadf2-0ca4-4e60-b8f3-cbb7e1dd3fe9",

"_type": "steps",

"steps": [

{

"_key": "afae879d-2675-4d60-bce6-867d88fa29b7",

"_type": "step",

"body": [

{

"_key": "oR5rmzJRTTTXSt7VQbhqAw",

"_type": "block",

"children": [

{

"_key": "oR5rmzJRTTTXSt7VQbhqBc",

"_type": "span",

"marks": [],

"text": "To drive success with early orders, drop your sales and campaigns at the onset of the holiday season—or even earlier. Take "

},

{

"_key": "oR5rmzJRTTTXSt7VQbhqCI",

"_type": "span",

"marks": [

"link-jxfy3qk"

],

"text": "POPFLEX"

},

{

"_key": "oR5rmzJRTTTXSt7VQbhqCy",

"_type": "span",

"marks": [],

"text": " as an example: the activewear brand promoted an early BFCM giveaway in October, then used the data they gathered from it to fine-tune their campaign messaging in time for a "

},

{

"_key": "oR5rmzJRTTTXSt7VQbhqDe",

"_type": "span",

"marks": [

"link-17pmjwd"

],

"text": "successful BFCM season"

},

{

"_key": "oR5rmzJRTTTXSt7VQbhqEK",

"_type": "span",

"marks": [],

"text": "."

}

],

"markDefs": [

{

"_key": "link-jxfy3qk",

"_type": "link",

"href": "https://www.popflexactive.com/",

"openInNewTab": true

},

{

"_key": "link-17pmjwd",

"_type": "link",

"href": "https://www.klaviyo.com/customers/case-studies/popflex-bfcm",

"openInNewTab": true

}

],

"style": "normal"

}

],

"title": "Launch your holiday sales and promotions early."

},

{

"_key": "f8d89e14-a912-465f-b252-b91ce983b70d",

"_type": "step",

"body": [

{

"_key": "oR5rmzJRTTTXSt7VQbhqF0",

"_type": "block",

"children": [

{

"_key": "oR5rmzJRTTTXSt7VQbhqFg",

"_type": "span",

"marks": [],

"text": "Encourage your customers to act fast by offering them an early-bird discount, free gift, or bundle promotion. Consider setting a specific date as a discount deadline and add countdown timers to your "

},

{

"_key": "oR5rmzJRTTTXSt7VQbhqGM",

"_type": "span",

"marks": [

"link-2tj7q7n"

],

"text": "forms"

},

{

"_key": "oR5rmzJRTTTXSt7VQbhqH2",

"_type": "span",

"marks": [],

"text": " and "

},

{

"_key": "oR5rmzJRTTTXSt7VQbhqHi",

"_type": "span",

"marks": [

"link-z8xw0zg"

],

"text": "emails"

},

{

"_key": "oR5rmzJRTTTXSt7VQbhqIO",

"_type": "span",

"marks": [],

"text": " to create a sense of urgency."

}

],

"markDefs": [

{

"_key": "link-2tj7q7n",

"_type": "link",

"href": "https://help.klaviyo.com/hc/en-us/articles/11206946148891",

"openInNewTab": true

},

{

"_key": "link-z8xw0zg",

"_type": "link",

"href": "https://help.klaviyo.com/hc/en-us/articles/115000780232",

"openInNewTab": true

}

],

"style": "normal"

}

],

"title": "Offer an incentive for shopping early."

},

{

"_key": "eef1abf1-414d-4ce9-b2d1-ef619ada1ba2",

"_type": "step",

"body": [

{

"_key": "oR5rmzJRTTTXSt7VQbhqJ4",

"_type": "block",

"children": [

{

"_key": "oR5rmzJRTTTXSt7VQbhqJk",

"_type": "span",

"marks": [],

"text": "Send emails promoting the softer advantages of ordering early, like convenience, reduced risk of delays, and peace of mind."

}

],

"markDefs": [],

"style": "normal"

}

],

"title": "Highlight the benefits of early shopping."

}

]

}

```

In this Black Friday promotional email, [Current Catalog](https://www.currentcatalog.com/), a brand that offers greeting cards, office supplies, and more, encourages shoppers to beat the holiday rush with a gift-themed message that emphasizes acting fast. In exchange for doing so, customers will receive free shipping plus 10% off all orders.

If you’re not a discount brand, you have other options for incentivizing your customers to order early. Here, beauty brand [Farmacy](https://www.farmacybeauty.com/) takes a more creative approach in their holiday promo email, offering those who “don’t delay” with their orders the option to gift now, pay later using Afterpay.

**Holiday shipping tip: **The opportunity to buy now, pay later is a [unique holiday incentive](https://www.klaviyo.com/blog/bfcm-email-marketing-strategy#decide-on-your-bfcm-offers-early-and-test-them2) that’s worth experimenting with instead of offering a universal discount in exchange for early orders. Other non-discount incentives to consider include free entry to a contest, free gifts with purchase, and free shipping when customers spend above a certain threshold.

Speaking of free shipping…

## 4. Consider offering free shipping

When customers pay for shipping, they may not be as accepting of potential issues with their orders. But offering free shipping might make them a bit more forgiving.

Before the season even begins, you can send out texts or emails to announce free shipping during the holidays and encourage shoppers to buy your products. Here, see how jewelry brand [Set & Stones](https://setandstones.com/) combines their free holiday shipping announcement with a “last chance” disclaimer to create urgency:

**Holiday shipping tip: **If offering free shipping on everything doesn’t make financial sense for your brand, consider these modified options:

- Set a minimum order threshold to qualify for free shipping.

- Offer the perk only to your [VIP customers](https://www.klaviyo.com/blog/how-to-identify-vip-customers).

- Build shipping into your product prices.

- Make free shipping available only for specific products.

## 5. Reduce mistakes in customer information

If your customers input the wrong information on your order or check-out page, it can trigger delays and issues with order fulfillment.

Here are a few steps you can take to minimize the risk of wrong phone numbers and addresses or typos in customer information:

- Create autofill forms where customer information is automatically populated with pre-saved information.

- Create forms with dropdown lists so that customers can choose from available options, rather than accidentally inputting invalid or incorrect data.

- Ask customers to provide an additional phone number if the primary one isn’t available.

- Highlight fields containing obvious errors, such as phone numbers with too many digits or non-existent addresses.

- Instruct customers to double-check their information before placing an order or add a pop-up that asks them to confirm the provided data.

**Holiday shipping tip: **A marketing platform like Klaviyo takes care of this for you by [capturing customer data](https://www.klaviyo.com/blog/what-is-a-customer-data-platform-cdp) from multiple systems, both internal and external, and storing that information in unique customer profiles. This way, your business can track customer behavior over time and be confident that the data you’ve collected is always accurate and up to date.

## 6. Share real-time order tracking

Customers appreciate transparency, so real-time order tracking can make them more likely to reorder. Plus, if they can track their orders live, they’ll be less likely to call your customer service team about their order status, and less likely to miss a delivery.

Keep every customer informed of their order status by providing them with a link for real-time tracking in your [transactional emails](https://www.klaviyo.com/blog/transactional-email) and [transactional texts](https://www.klaviyo.com/blog/transactional-sms). This way, they can see changes as they happen, so they don’t have to wonder what’s going on with their shipment.

Share tracking links in your order and shipping confirmation email and texts, like vegan skincare brand [OSEA](https://oseamalibu.com/) does here:

**Holiday shipping tip: **SMS is a particularly smart channel for transactional updates. According to Klaviyo’s [2024 global texting takeaways report](https://www.klaviyo.com/marketing-resources/sms-consumer-report), transactional messages are the No. 1 type of communication consumers prefer to receive via SMS rather than email.

## 7. Suggest alternatives for out-of-stock products

From one perspective, running out of inventory during the holiday season is a compliment: it means people love your product. But it means you’re guaranteed to end up with some unhappy customers.

To make the most of a potentially bad situation, use email and SMS to suggest product alternatives your customers can order right away, or [enable back-in-stock notifications](https://help.klaviyo.com/hc/en-us/articles/115003872251) to let shoppers know when they can come back to order what they wanted without delays.

Here, footwear brand [Kizik](https://kizik.com/) gets ahead of Cyber Monday stockout issues by sending an apologetic email along with a link to alternative shoe styles disappointed shoppers can browse:

Stamp and dye brand [My Favorite Things](https://www.mftstamps.com/), meanwhile, avoids missing out on Christmas sales by sending out a back-in-stock email inviting customers to continue shopping for the gifts they originally wanted:

## 8. Offer local pickup options for customers in your area

To help minimize the burden on the transportation industry and get your products in the hands of your customers faster, you can arrange local pickups for customers in your area so they don’t have to pay for shipping or wait days to receive their orders.

This option also means you don’t have to coordinate shipping and can save on packaging materials and resources.

Here, cosmetics brand [Sly Beauty](https://slybeautycosmetics.com/) spreads the word about their local pickup option in an email campaign _before_ customers place their orders. The straightforward email clearly outlines the location, dates, and times when pickup will take place, as well as a short explanation of how to select this option when checking out online:

**Holiday shipping tip: **If you offer local pickup, make sure you add it as an option during your check-out process. Then, update your order confirmation email templates to include details on exactly when and where customers can pick up their items.

## 9. Set up additional fulfillment centers or find a 3PL partner

Shipping from a single location may be more convenient, but it’s also risky—in case of severe weather in the area or not enough hands on deck, you’ll have no way to ship orders.

Instead of keeping all your eggs in one geographical basket, it’s a good idea to set up additional fulfillment centers to streamline your operations and ensure timely deliveries.

Of course, for many ecommerce brands, this is easier said than done.

In the meantime, consider a more affordable and realistic option: partnering with a third-party logistics (3PL) company to help with order fulfillment and keeping your team’s heads above water.

**Holiday shipping tip: **Klaviyo has built-in integrations with a wide variety of [shipping, logistics, and 3PL platforms](https://integrations.klaviyo.com/?categories=shippinglogistics).

## 10. Analyze and improve

Once the holidays are over and the excitement settles down, take some time to reflect on the season behind you. Analyze your workflows, shipping policies, and timelines, talk to your suppliers, and see what worked well and what requires improvement.

Gathering customer feedback is another vital part of this process. Once customers receive their orders, ask them about their experience and overall satisfaction with the process, like genderless apparel brand Wildfang does with this [review request email](https://www.klaviyo.com/blog/ecommerce-reviews#how-to-collect-customer-reviews-for-your-ecommerce-business). You can use the information you collect to improve your processes down the line.

By conducting a thorough analysis of your holiday season’s ups and downs, you’ll lay the groundwork for the year ahead. This will lead to even more satisfied customers and fewer issues down the line.

**Holiday shipping tip: **Collecting [user-generated content](https://www.klaviyo.com/blog/user-generated-content-ugc) like customer reviews and testimonials is a great way to let your happiest customers do your marketing for you. Take a leaf out of [Compass Coffee](https://www.compasscoffee.com/)’s book and set up your review request flows to incentivize customers to leave [reviews with a visual element](https://www.klaviyo.com/customers/case-studies/compass-coffee-reviews), which will be easier to incorporate into your marketing efforts.

## Keep your promises to your customers with Klaviyo

Sometimes, holiday shipping delays are inevitable despite your best efforts. They can result from factors beyond your control, such as bad weather, carrier strikes, or transportation issues.

But as long as you do everything in your power to keep your customers informed about the status of their orders, you’ll be on the right track to overcoming shipping delay troubles and making it out of the holiday season with your most prized customer relationships intact.

Customer satisfaction should be at the forefront of your priorities all year long—not just when the fallout from a global shipping backlog threatens to erode your brand’s reputation. The key, as usual, is clear communication. With the right [email and SMS automations](https://www.klaviyo.com/marketing-resources/email-sms-marketing-integration), your customers will always know exactly what to expect.

Klaviyo helps you manage your [post-purchase communications](https://www.klaviyo.com/blog/post-purchase-emails) with maximum transparency, protecting your brand’s bottom line during the most wonderful, and hectic, time of the ecommerce year.

### Related content

- [Email marketer’s guide to shipping delay announcements](https://www.klaviyo.com/blog/communicate-shipping-delays-coronavirus)

- [10 tips for sending a shipping confirmation email that converts](https://www.klaviyo.com/blog/tips-better-shipping-confirmation-emails)

- [4 successful transactional email examples: clarity wins every time](https://www.klaviyo.com/blog/transactional-email-examples)

```json

{

"_createdAt": "2026-01-20T02:17:22Z",

"_id": "06fecae6-d4eb-45d1-952e-ce25a54e46ee",

"_key": "oR5rmzJRTTTXSt7VQbhsCG",

"_ref": "06fecae6-d4eb-45d1-952e-ce25a54e46ee",

"_rev": "68kkAEoTsuAyP6YqnZQYdk",

"_type": "ctaDocument",

"_updatedAt": "2026-01-20T02:17:22Z",

"button": {

"_key": "d2199339-8f4e-4628-b452-6480a2ed9580",

"_type": "button",

"buttonText": "Sign up",

"buttonType": "primary",

"buttonUrl": "https://www.klaviyo.com/sign-up"

},

"content": [

{

"_key": "e565171c-c044-4ee4-8d12-bdadb7caacd0",

"_type": "block",

"children": [

{

"_key": "4f85995e-5538-4a36-b633-03b239b85ae3",

"_type": "span",

"marks": [],

"text": "Ready to overcome shipping delays with Klaviyo?"

}

],

"markDefs": [],

"style": "normal"

}

]

}

```